I. Application Background

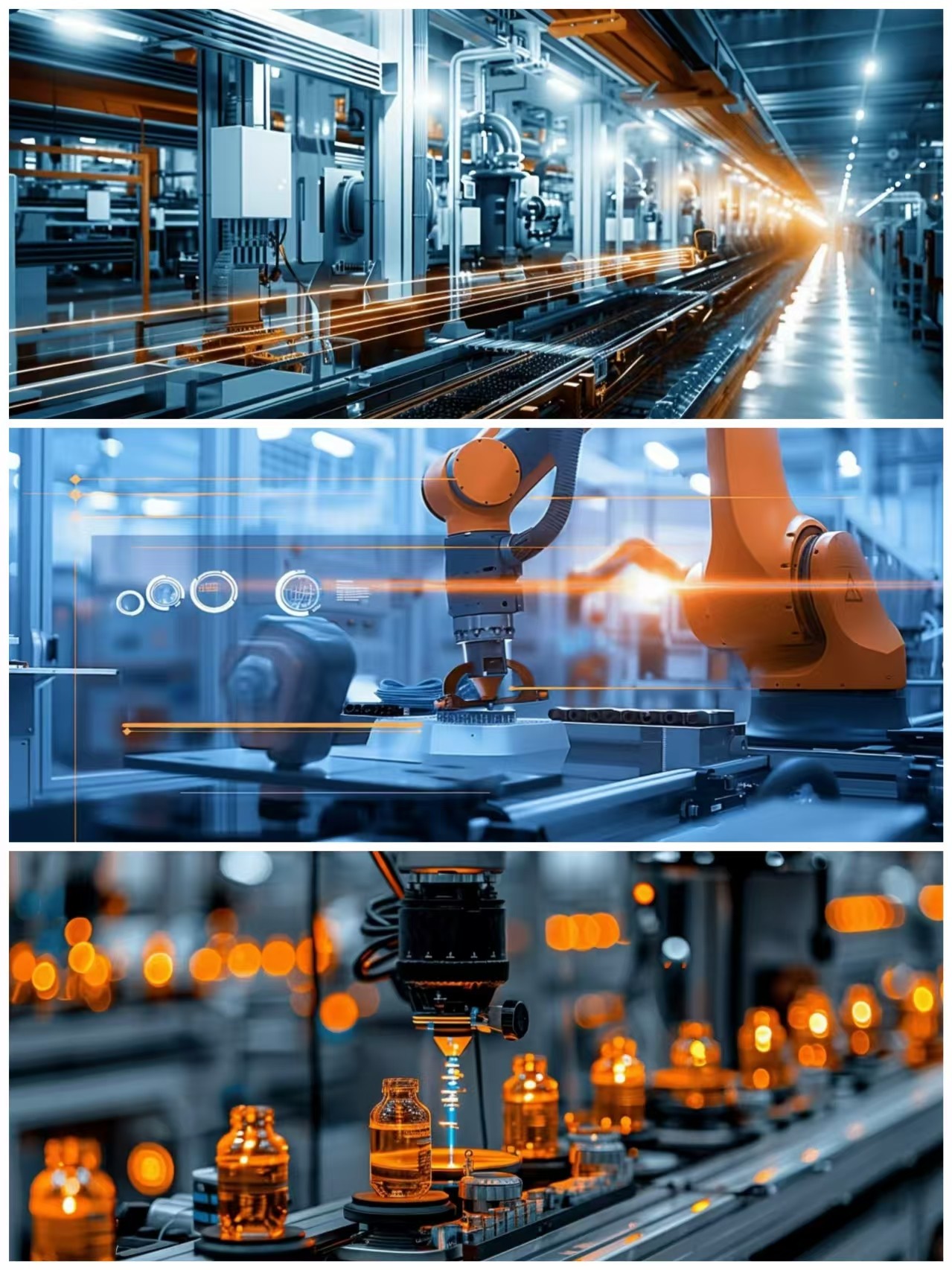

With the development of industrial automation, industrial robots, as the core of automated production lines, continue to show high efficiency, precision and reliability. Industrial robots are moving towards the direction of higher motion beat, higher precision, higher load bearing and more compact structure, and signal transmission between key core components such as servo motors and harmonic reducers is becoming more and more important. Circular connectors are gradually becoming an indispensable part of them, especially in the automatic welding production line, its advantages are more and more significant.

Advantages of Machiyo Circular Connectors

High performance and reliability:

Machiyo circular connectors have high performance and high reliability of electrical interconnections, and are able to maintain durability, dustproof and high temperature resistance in the harsh environment of welding.

The metal housing and sealing structure, as well as the IP68 protection rating, can effectively prevent the external environment from affecting the connector and ensure the continuity and stability of the soldering process.

It supports stable transmission of various signals and power supplies:

Dinkle circular connectors can meet the signal and power transmission requirements in different scenarios to ensure the normal operation of industrial robot welding production lines.

In the 3C electronic welding production line, Dinkle Circular Connector adopts high-speed transmission technology, which can realize fast and stable data transmission and precise welding control, and improve production efficiency and product quality.

Modular design, flexible adaptation to different needs:

Dinkle circular connectors adopt modular design, different combinations of plugs and sockets can be selected according to the actual needs, realizing flexible connection methods.

This design makes the connector compatible with different welding processes and equipment, improving the productivity and debugging efficiency of the equipment.

Third, the specific application cases

Automotive welding production line:

The working environment of automobile welding is often accompanied by splashing high-temperature sparks and choking pungent welding slag fumes.

In the process of automatic welding by industrial robots, Machiyo circular connectors can withstand high temperature, high pressure and high frequency working environment to ensure the stability and continuity of the welding process.

3C electronic welding production line:

3C electronic welding production line requires high data transmission speed and bandwidth of the connector.

Dinkle circular connectors adopt high-speed transmission technology, which can meet this demand and ensure accurate operation and real-time control of the robot during the welding process.

Agricultural machinery structure welding production line:

Connectors on agricultural machinery structure welding production lines need to be adapted to different welding processes and equipment.

The modular design of Machinima's circular connectors allows them to be flexibly adapted to these needs, increasing equipment productivity and commissioning efficiency.

Machinima's circular connectors play an important role in industrial robot welding lines due to their high performance, high reliability and flexible design. They support stable transmission of multiple signals and power supplies, meeting the needs of different scenarios and improving productivity and product quality. With the continuous development of welding technology, the application prospect of Machiyo's circular connectors in the field of industrial automation will be more broad.